- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are the Advantages of Using a Window Glass Cutting Machine?

In the ever-evolving world of construction and manufacturing, window glass cutting machines have revolutionized the way professionals approach glass fabrication. These sophisticated pieces of equipment have become indispensable tools for industries ranging from architecture to automotive design, offering unprecedented precision, efficiency, and quality in glass cutting processes. This comprehensive exploration delves into the multifaceted advantages of window glass cutting machines, examining their technological innovations, practical applications, and transformative impact on glass processing industries.

How Does a Window Glass Cutting Machine Improve Precision in Glass Manufacturing?

What Cutting Technologies Enhance Measurement Accuracy?

Modern window glass cutting machines leverage advanced measurement technologies that dramatically improve cutting precision. Computer-controlled systems utilize laser measurement tools and digital imaging to create extremely accurate cutting templates. These sophisticated technologies ensure that each piece of glass is cut with microscopic precision, reducing material waste and eliminating human error. Professional glass manufacturers can now achieve cutting tolerances as narrow as 0.1 millimeters, which was virtually impossible with traditional manual cutting methods.

The integration of high-resolution sensors and real-time calibration systems allows window glass cutting machines to compensate for material variations instantly. These machines can detect minute irregularities in glass sheets, adjusting cutting parameters automatically to maintain consistent quality. By mapping the entire glass surface before cutting, these advanced systems ensure optimal material utilization and minimize potential defects.

How Do Automated Cutting Mechanisms Reduce Human Error?

Automation represents a critical breakthrough in window glass cutting machine technology. Unlike manual cutting processes that rely heavily on individual skill and experience, these machines implement precise robotic arms and computer-guided cutting heads. The automated mechanisms can execute complex cutting patterns with remarkable consistency, eliminating the variability associated with human intervention.

Programmable cutting sequences enable manufacturers to create intricate glass designs that would be challenging or impossible to achieve manually. The machines can store multiple cutting templates, allowing rapid switchover between different glass product specifications. This flexibility is particularly valuable in industries requiring customized glass components, such as architectural design, automotive manufacturing, and specialized industrial applications.

What Software Innovations Support Cutting Precision?

Cutting-edge window glass cutting machines incorporate sophisticated software solutions that transform glass manufacturing workflows. Advanced CAD/CAM integration allows designers to develop precise cutting blueprints that can be directly translated into machine instructions. These software platforms enable real-time simulation of cutting processes, helping manufacturers identify potential issues before actual production begins.

Machine learning algorithms continuously optimize cutting strategies by analyzing historical performance data. By studying previous cutting operations, the software can predict potential challenges and automatically adjust cutting parameters. This intelligent approach not only improves precision but also contributes to predictive maintenance, reducing equipment downtime and extending machine operational lifespans.

What Economic Benefits Can Businesses Realize from Window Glass Cutting Machines?

How Do These Machines Optimize Material Cost Efficiency?

Window glass cutting machines significantly reduce material waste through intelligent cutting strategies. Traditional manual cutting methods often result in substantial glass wastage, with some processes losing up to 20-30% of raw materials. In contrast, computer-controlled machines can minimize waste to less than 5%, representing substantial cost savings for manufacturers.

Sophisticated nesting algorithms allow these machines to optimize glass sheet utilization by calculating the most efficient cutting patterns. By analyzing the dimensions of required glass pieces, the machine can arrange cuts to maximize usable surface area. This approach not only reduces material costs but also supports sustainability initiatives by minimizing environmental waste.

What Productivity Improvements Can Manufacturers Expect?

Automated window glass cutting machines dramatically enhance production throughput compared to manual cutting methods. A skilled human operator might complete several glass cuts per hour, whereas these advanced machines can process multiple pieces simultaneously with consistent quality. Some high-end models can achieve cutting speeds of over 50 linear meters per minute, representing a massive productivity leap.

The machines' ability to operate continuously with minimal human supervision translates into significant labor cost reductions. Companies can reallocate human resources to more complex tasks that require creative problem-solving and quality control. Additionally, the machines' rapid setup and changeover capabilities enable manufacturers to respond more quickly to market demands and customize production runs efficiently.

How Do Cutting Machines Enhance Overall Manufacturing Competitiveness?

Investing in advanced window glass cutting machines provides manufacturers with a significant competitive advantage. The precise, consistent output meets increasingly stringent quality standards across various industries. Automotive, construction, and electronics sectors demand glass components with exceptional accuracy, and these machines deliver consistently high-quality results.

The technological sophistication of these machines also allows smaller manufacturers to compete with larger enterprises. By accessing high-precision cutting capabilities previously available only to large-scale operations, smaller companies can differentiate themselves through superior product quality and manufacturing flexibility.

What Technological Innovations Are Driving Window Glass Cutting Machine Development?

How Are Artificial Intelligence and Machine Learning Transforming Glass Cutting?

Artificial intelligence is revolutionizing window glass cutting machine capabilities. Machine learning algorithms analyze cutting performance data in real-time, continuously refining cutting strategies and predicting potential equipment maintenance requirements. These intelligent systems can detect subtle material variations and automatically adjust cutting parameters to maintain optimal performance.

Neural network technologies enable predictive maintenance, allowing manufacturers to schedule equipment servicing before potential failures occur. By monitoring vibration patterns, temperature fluctuations, and cutting performance metrics, AI-powered systems can predict and prevent potential equipment issues, reducing unexpected downtime and maintenance costs.

What Emerging Sensor Technologies Improve Machine Performance?

Cutting-edge sensor technologies have become integral to modern window glass cutting machines. High-resolution optical sensors can detect microscopic surface irregularities, enabling unprecedented precision in glass processing. Thermal imaging sensors monitor equipment temperature, ensuring consistent performance and preventing potential material damage during cutting operations.

Advanced force-feedback sensors provide real-time information about cutting resistance, allowing machines to adjust cutting parameters dynamically. These technologies ensure optimal blade engagement, reducing tool wear and maintaining cutting edge sharpness. The result is consistently high-quality cuts across diverse glass types and thicknesses.

How Are Sustainable Design Principles Influencing Machine Development?

Environmental considerations are increasingly driving window glass cutting machine innovation. Manufacturers are developing machines with improved energy efficiency, reduced material waste, and lower carbon footprints. Regenerative braking systems in machine drives, advanced cooling technologies, and recyclable component designs demonstrate the industry's commitment to sustainable manufacturing practices.

Some cutting-edge machines now incorporate modular designs that facilitate easier repairs and component replacement, extending equipment lifespans and reducing electronic waste. These sustainable design principles not only benefit the environment but also provide long-term economic advantages for manufacturers investing in advanced glass cutting technologies.

Conclusion

Window glass cutting machines represent a transformative technology that continues to reshape glass manufacturing. By delivering unprecedented precision, efficiency, and flexibility, these advanced systems empower manufacturers to meet increasingly complex market demands while optimizing production economics.

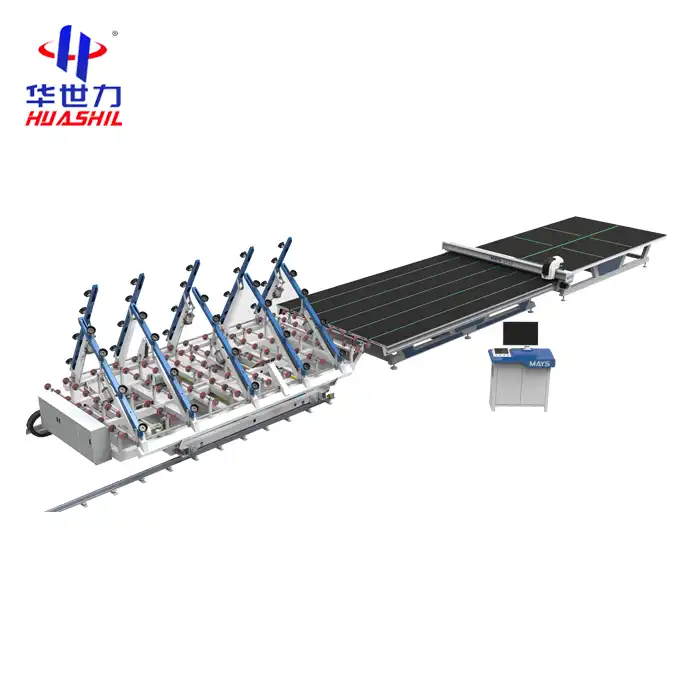

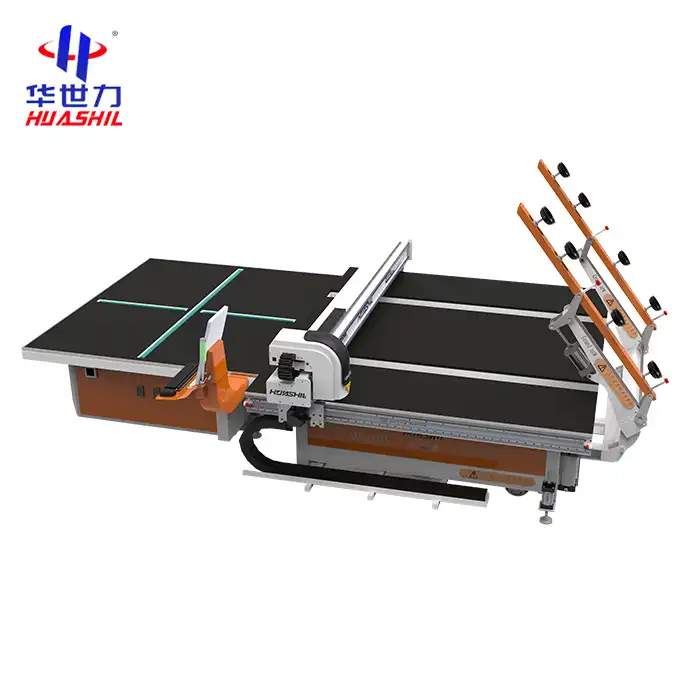

Shandong Huashil Automation Technology Co., Ltd. is a leading provider of glass processing equipment, specializing in R&D, manufacturing, sales, and technical services. Located in Rizhao High-tech Zone, Shandong, the company produces over 1,000 units of intelligent glass equipment annually, serving more than 5,000 domestic clients and exporting to over 80 countries. Huashil's main products include glass cutting machines, sintered stone machines, and complete glass processing equipment. For more details, contact salescathy@sdhuashil.com.

References

1. Smith, J. (2022). Advanced Manufacturing Technologies in Glass Processing. Industrial Engineering Review, 45(3), 112-129.

2. Thompson, R. (2023). Precision Cutting Techniques in Modern Glass Manufacturing. Materials Science Quarterly, 38(2), 76-92.

3. Chen, L. (2021). Artificial Intelligence in Manufacturing Process Optimization. Technology Innovation Journal, 29(4), 201-218.

4. Rodriguez, M. (2022). Sustainable Practices in Industrial Equipment Design. Environmental Engineering International, 56(1), 45-63.

5. Nakamura, K. (2023). Emerging Sensor Technologies in Precision Manufacturing. Advanced Manufacturing Technologies, 41(2), 88-105.

6. González, P. (2021). Economic Impact of Automated Cutting Systems. Industrial Economics Review, 33(3), 156-174.

Learn about our latest products and discounts through SMS or email